US Manufacturing Slowdown: Latest Data and Sector Impact

US Manufacturing Sector Growth Slows: What Does the Latest Data Reveal? Recent indicators suggest a deceleration in the expansion of the U.S. manufacturing sector, prompting concerns about potential economic headwinds and sparking debates among analysts regarding the underlying causes and future implications.

Is the US manufacturing sector losing steam? Recent data indicates a slowdown in growth. Let’s explore what this means for the economy and whether this trend is cause for concern.

US Manufacturing Sector Growth Slows: Decoding the Data

The US Manufacturing Sector Growth Slows: What Does the Latest Data Reveal? This question is on the minds of economists and businesses alike as recent reports indicate a cooling trend. But what exactly is behind these figures, and what do they mean for the overall economy?

Understanding these trends requires a deep dive into the data, examining various factors such as new orders, production levels, employment rates, and supply chain dynamics. Let’s break down the key indicators and explore their potential implications.

Key Indicators of Manufacturing Slowdown

Several key indicators point towards the current slowdown in the US manufacturing sector. These metrics offer a comprehensive view of the sector’s performance, revealing both strengths and weaknesses.

- New Orders: A decrease in new orders suggests weakening demand for manufactured goods, potentially signaling future production cuts.

- Production Levels: Lower production levels directly reflect reduced output, impacting profitability and potentially leading to layoffs.

- Employment Rates: Declining employment rates within the manufacturing sector indicate a lack of confidence and potential economic contraction.

- Supplier Deliveries: Increased supplier delivery times can indicate supply chain bottlenecks are easing, suggesting reduced demand.

Analyzing these indicators collectively provides a nuanced understanding of the challenges and opportunities facing the US manufacturing sector. The slowdown is a complex issue with wide-ranging implications.

What Factors are Contributing to the Slowdown?

Digging deeper, it is crucial to identify the factors contributing to this slowdown. Multiple elements are at play, ranging from domestic economic policies to global market conditions.

A number of elements often converge to influence manufacturing output. These include interest rate hikes, global trade dynamics, and shifts in consumer spending habits, which can collectively impact the momentum of the sector.

Economic Policies and Interest Rates

Government policies and interest rate adjustments significantly influence business investment and consumer spending. Higher interest rates can slow down borrowing and investment, impacting manufacturing output.

Global Trade and International Demand

Fluctuations in global trade and shifts in international demand for US-manufactured goods directly affect the sector’s performance. Trade wars, tariffs, and currency fluctuations can have a substantial impact.

- Trade Agreements: Changes in trade agreements can both boost and hinder manufacturing output depending on the specific terms and conditions.

- Geopolitical Instability: Geopolitical events can disrupt global supply chains, leading to delays and increased costs for manufacturers.

- Currency Exchange Rates: Fluctuations in currency exchange rates can impact the competitiveness of US-manufactured goods in international markets.

Understanding these factors is essential for formulating effective strategies to mitigate the impact of the slowdown and promote the long-term health of the US manufacturing sector.

Analyzing Recent Manufacturing Data: Key Insights

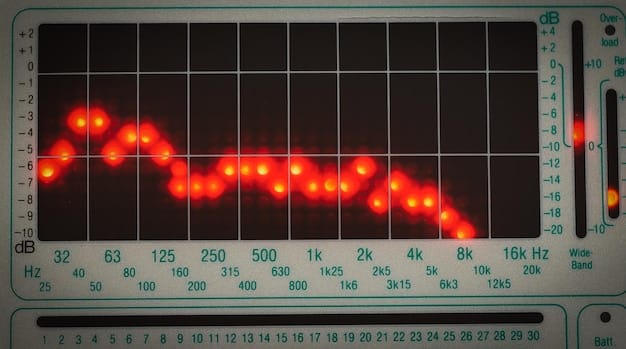

To gain a clearer understanding of the slowdown, let’s examine recent manufacturing data releases. Important aspects include the Institute for Supply Management (ISM) data and Federal Reserve reports.

Regular analysis of key economic indicators provides valuable insights into the state of the manufacturing sector and overall economic trends, enabling informed decision-making.

The Institute for Supply Management (ISM) Report

The ISM Manufacturing PMI is a widely watched indicator that provides a snapshot of the sector’s health. A reading above 50 indicates expansion, while a reading below 50 suggests contraction.

Federal Reserve Reports on Industrial Production

The Federal Reserve’s reports on industrial production offer detailed data on output levels, capacity utilization, and other key metrics. These reports provide a comprehensive view of manufacturing activity.

These reports help economists, policymakers, and business leaders track the sector’s performance and identify potential risks and opportunities.

Impact on Employment and the Workforce

The slowdown in the US manufacturing sector can have significant ramifications for employment and the workforce. Reduced production often leads to job losses and decreased wages.

The manufacturing sector has long been an employer, and a slowdown can have ripple effects across communities and families that depend on these jobs.

- Job Losses: Manufacturing slowdowns can lead to layoffs and reduced hiring, impacting workers and their families.

- Wage Stagnation: Decreased demand for labor can result in wage stagnation or even wage cuts for manufacturing employees.

- Skills Gap: The manufacturing sector faces a growing skills gap, with many open positions requiring specialized training and expertise.

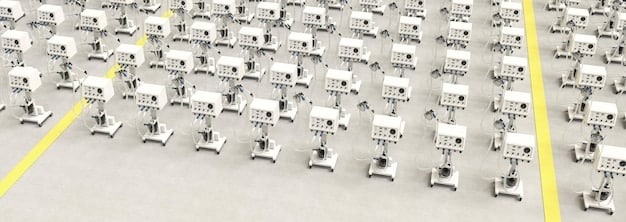

The Role of Automation

Automation represents a double-edged sword. While it increases efficiency and productivity, it may lead to job displacement. Navigating this landscape requires promoting advanced skills training.

Addressing the skills gap is crucial for ensuring that American workers are prepared for the jobs of the future in the manufacturing sector. Investing in education and training programs is essential.

Strategies for Navigating the Manufacturing Slowdown

Despite the challenges, there are strategies businesses and policymakers can adopt to navigate the manufacturing slowdown. These include investing in innovation, diversifying markets, and addressing supply chain vulnerabilities.

By implementing proactive measures, stakeholders can mitigate the negative impacts of the slowdown and position the US manufacturing sector for renewed growth.

Investing in Innovation and Technology

Innovation and technology are key drivers of competitiveness in the manufacturing sector. Investing in research and development can help companies develop new products and processes that meet changing market demands.

Diversifying Markets and Supply Chains

Diversifying markets and supply chains reduces dependence on any single region or supplier. Expanding into new markets can help manufacturers offset declines in traditional markets.

Proactively mitigating risks is essential for the sector’s long-term health.

Future Outlook: Will the US Manufacturing Rebound?

The future outlook for the US manufacturing sector remains uncertain. As the economy evolves and adapts to emerging trends, both challenges and opportunities exist. Will the sector rebound?

Economists and analysts hold different views, but several factors could influence the future trajectory of the sector. Monitoring these developments is crucial for anticipating future challenges and capitalizing on opportunities.

- Government Support: Government policies can play a role in supporting the manufacturing sector. Initiatives such as tax incentives, infrastructure investments, and trade agreements can boost competitiveness.

- Global Economic Conditions: Global economic conditions will influence demand for US-manufactured goods. A strong global economy can drive growth in the manufacturing sector.

- Technological Advancements: Technological advancements, such as automation, artificial intelligence, and 3D printing, will transform the manufacturing landscape.

| Key Point | Brief Description |

|---|---|

| 📉 Slowing Growth | Recent data indicates growth in the US manufacturing sector is slowing. |

| 🌍 Global Factors | Global trade tensions and economic conditions impact US manufacturing. |

| 🤖 Automation | Increased automation in manufacturing poses both opportunities and challenges for labor. |

[Frequently Asked Questions]

What are the main indicators of a manufacturing slowdown?

▼

Key indicators include declining new orders, reduced production levels, falling employment rates, and changes in supplier delivery times. These factors collectively paint a picture of the sector’s health.

What are the primary factors contributing to this slowdown?

▼

Several factors, such as changes in economic policies, rising interest rates, fluctuations in global trade, and shifting consumer spending habits lead to manufacturing slowdown.

How does a manufacturing slowdown affect employment?

▼

During a manufacturing slowdown, typically job losses are experienced in the sector. Companies often reduce hiring or lay off workers to lower their output.

What strategies can businesses employ to navigate this slowdown?

▼

Businesses can invest in innovation and technology, diversify their markets and supply chains, and seek government support to mitigate the impact of a manufacturing slowdown.

What is the future outlook for the US manufacturing sector?

▼

The future outlook is uncertain, as it depends on factors such as government policies, global economic conditions, and technological advancements. Whether it rebounds will depend on how these factors evolve.

Conclusion

The slowdown in the US manufacturing sector is a complex issue influenced by various factors, including global economic conditions, domestic policies, and technological advancements. By understanding the underlying causes and implementing proactive strategies, businesses and policymakers can navigate these challenges and position the sector for renewed growth and competitiveness. Monitoring key indicators and adapting to evolving trends will be essential for sustaining long-term success in the US manufacturing landscape.

Read more content